Häufig gestellte Fragen

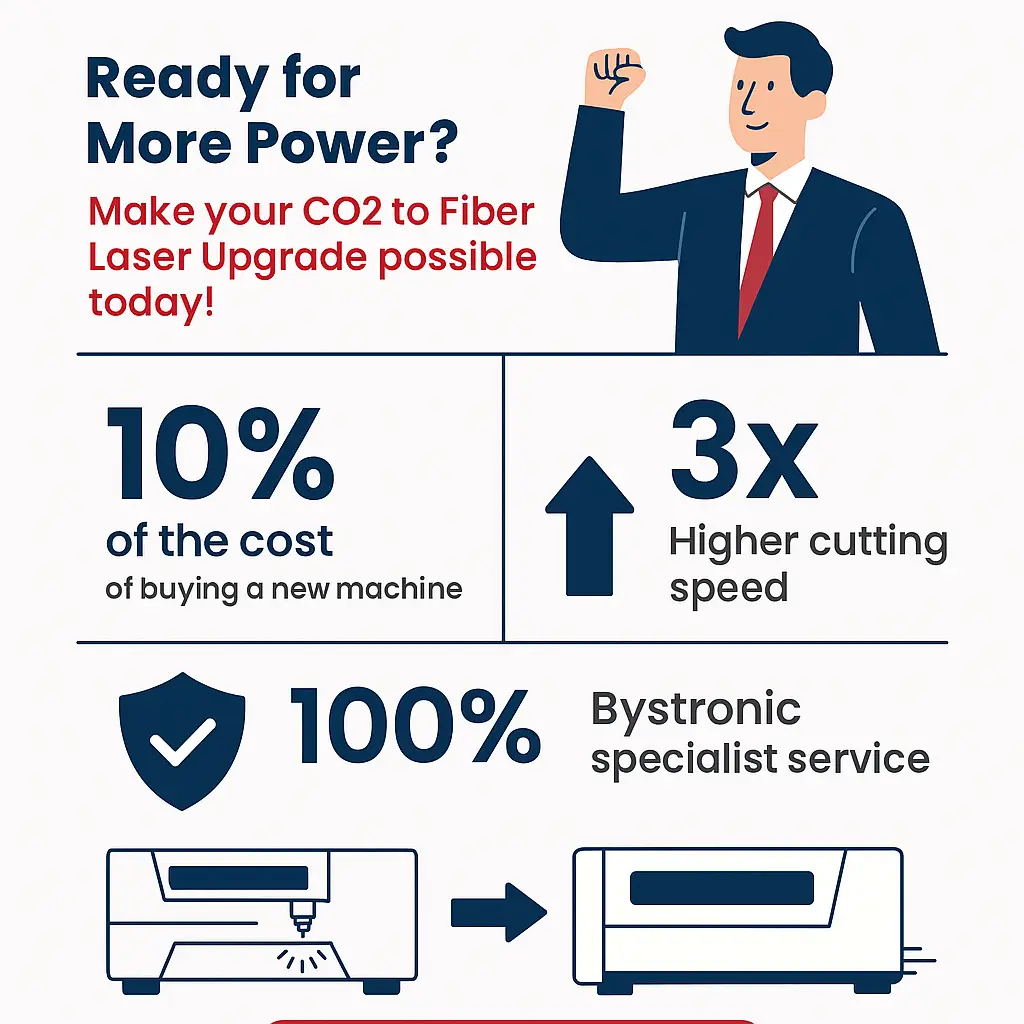

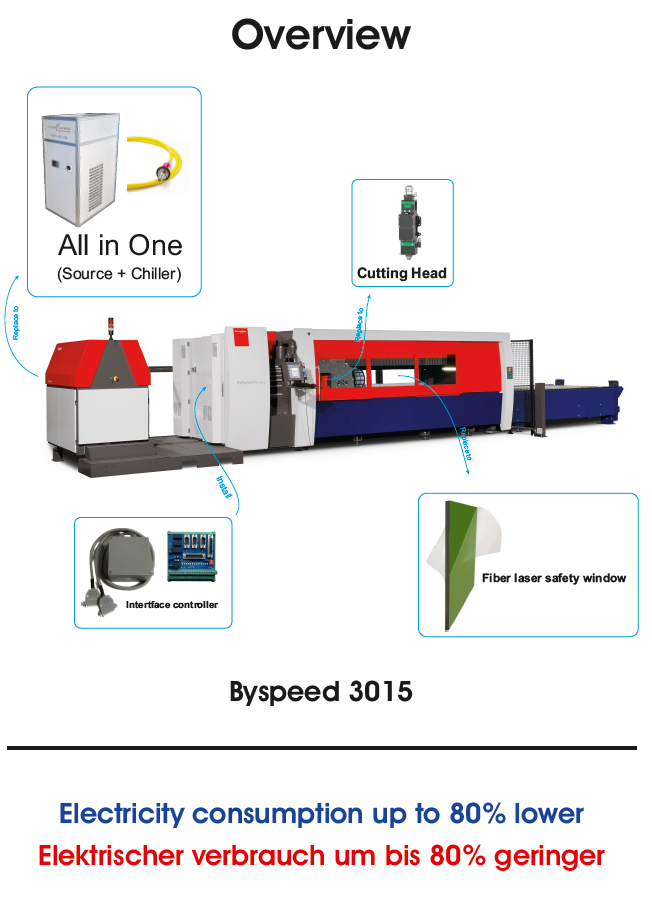

On average, the complete retrofit including test runs takes less than 3 working days.

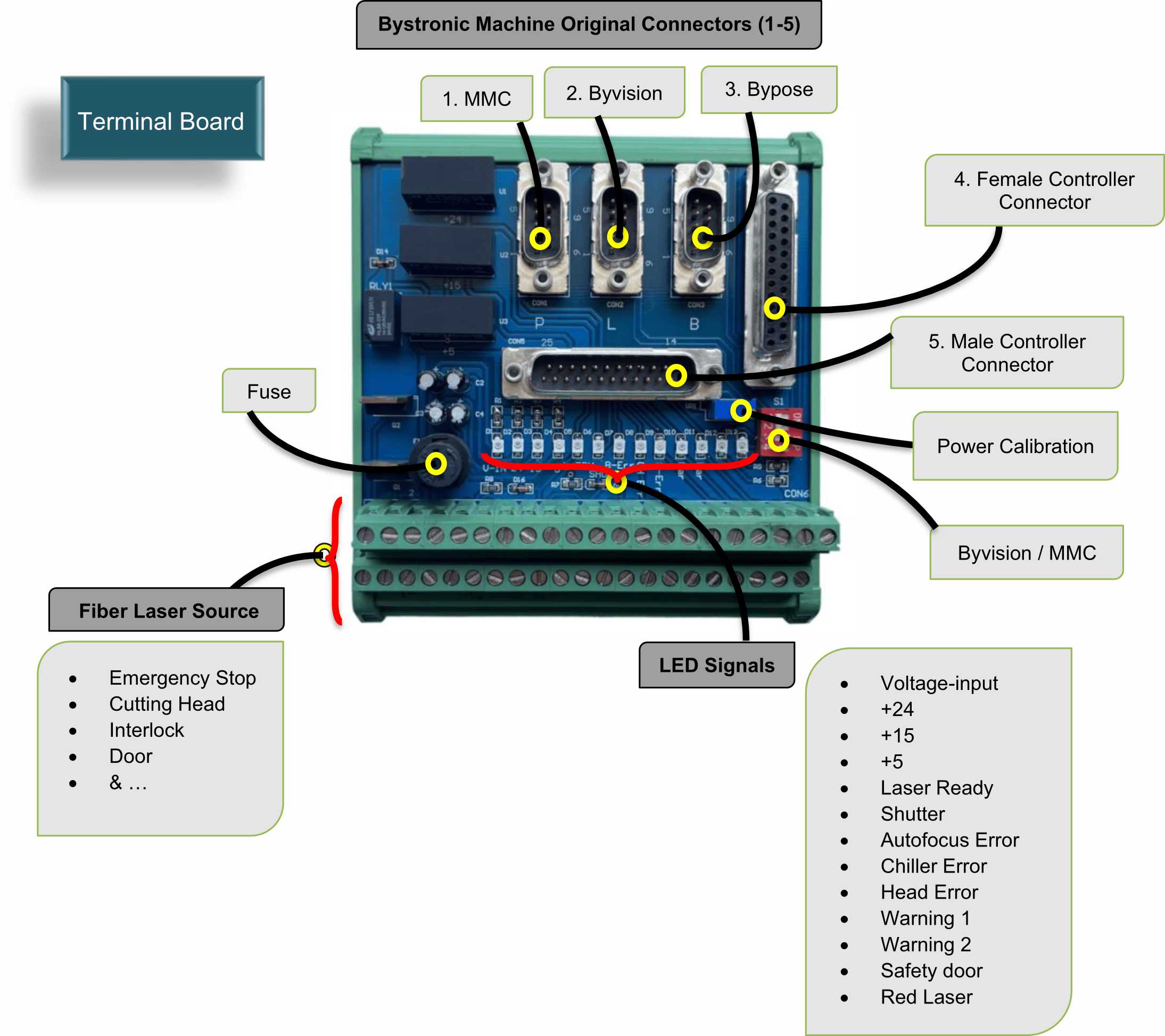

No, your existing Bystronic control system remains unchanged – no additional training is required.

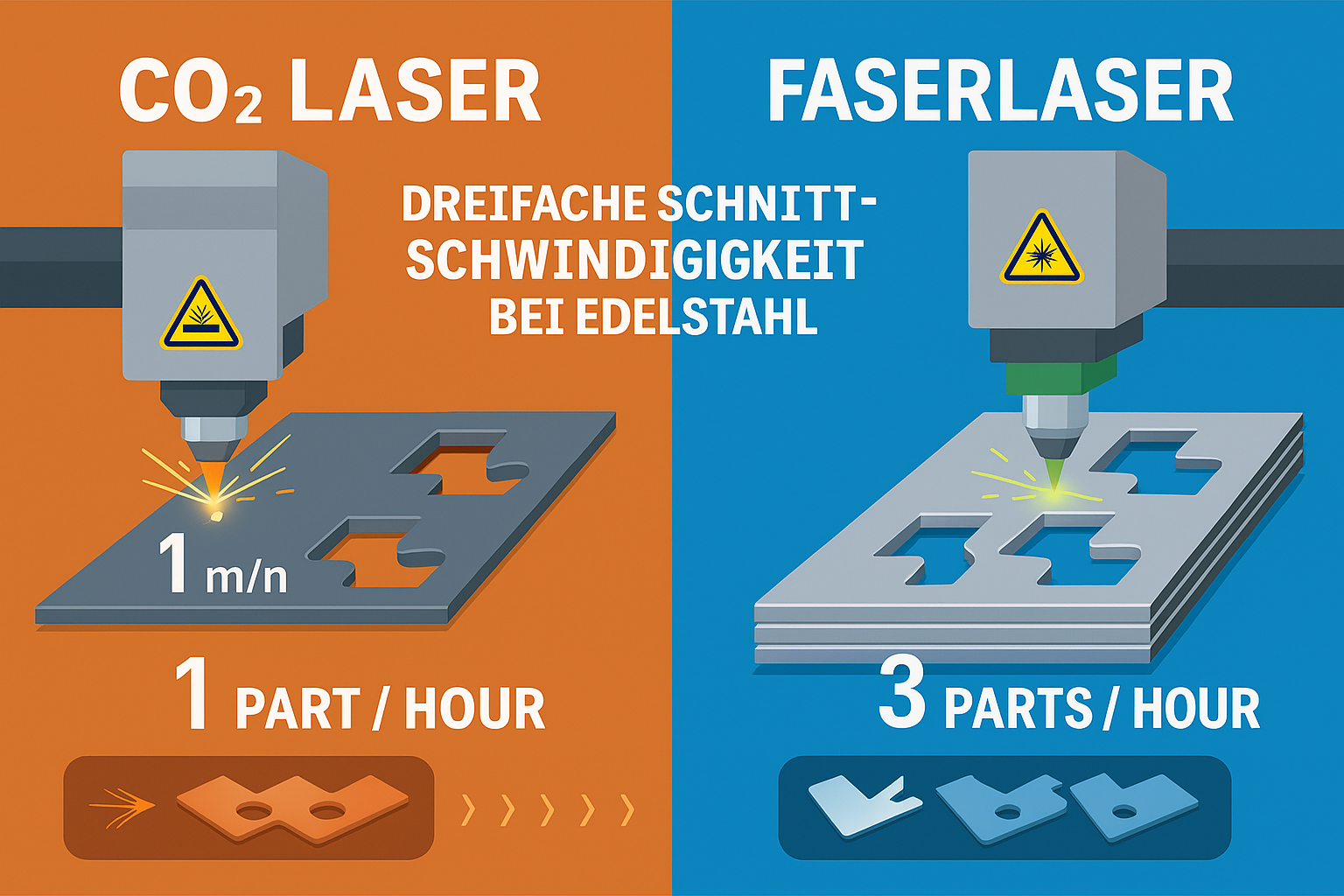

All common metals – including stainless steel, aluminum, copper, and brass – with just one cutting head.

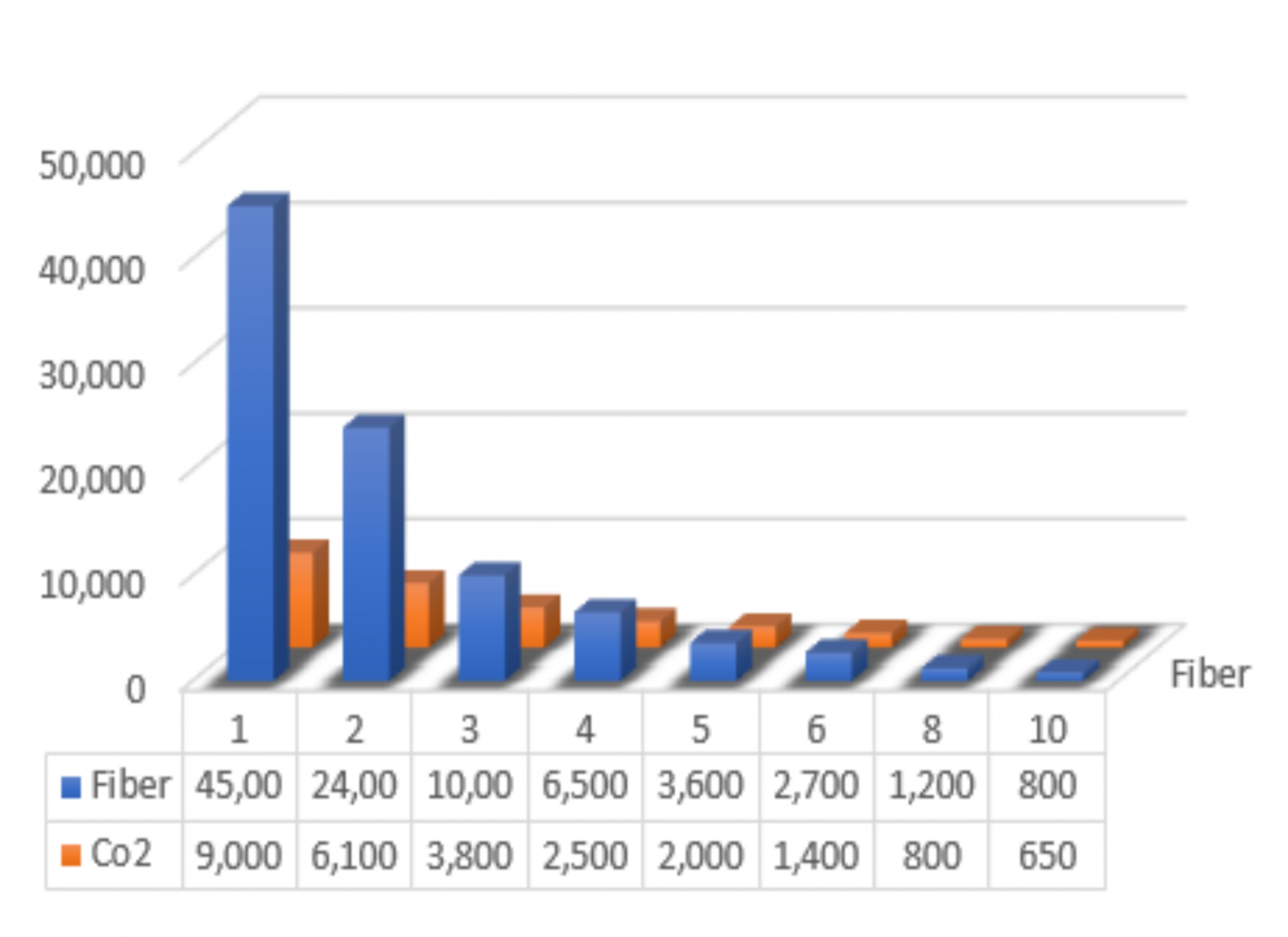

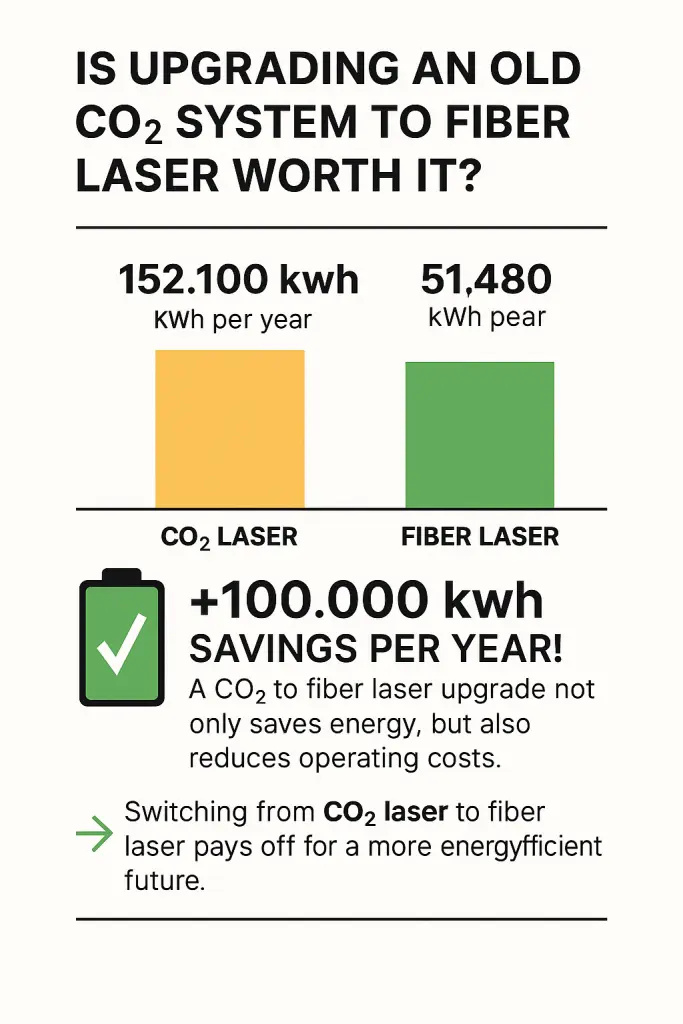

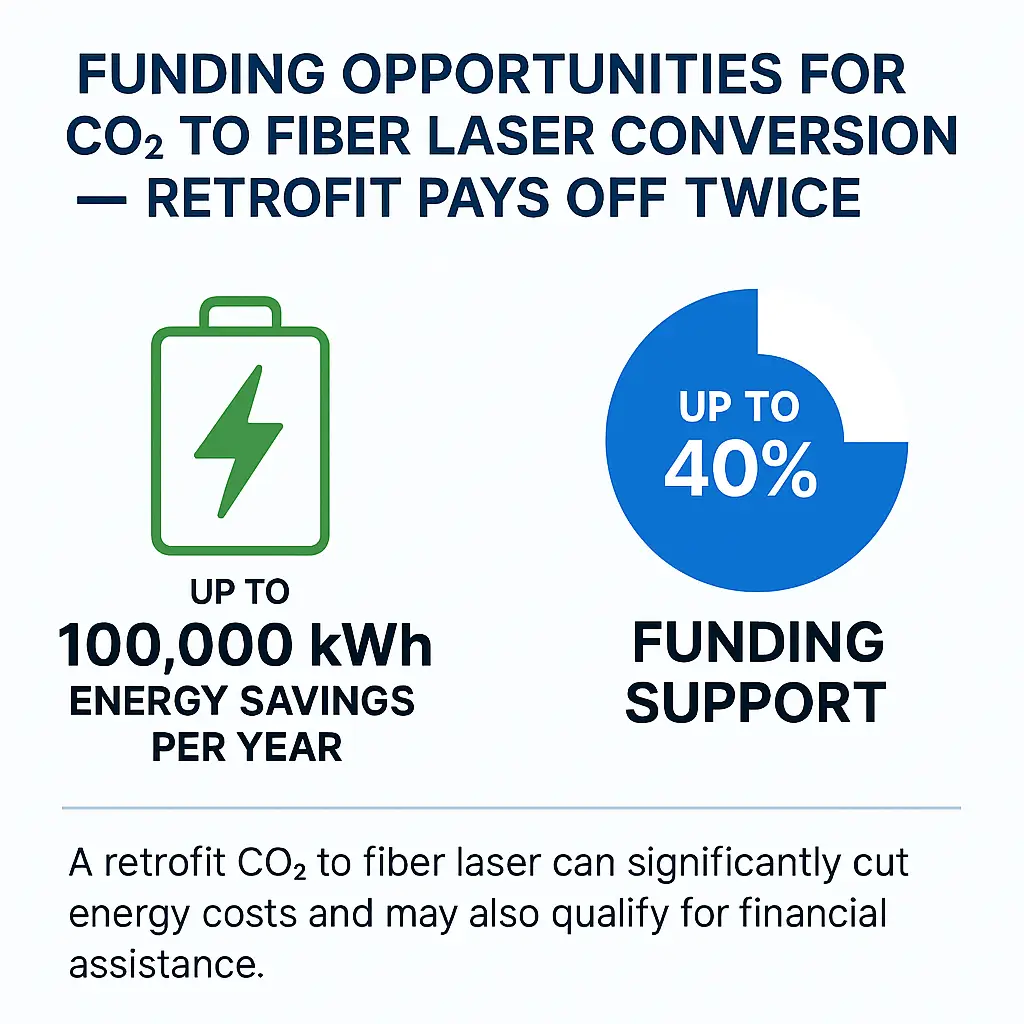

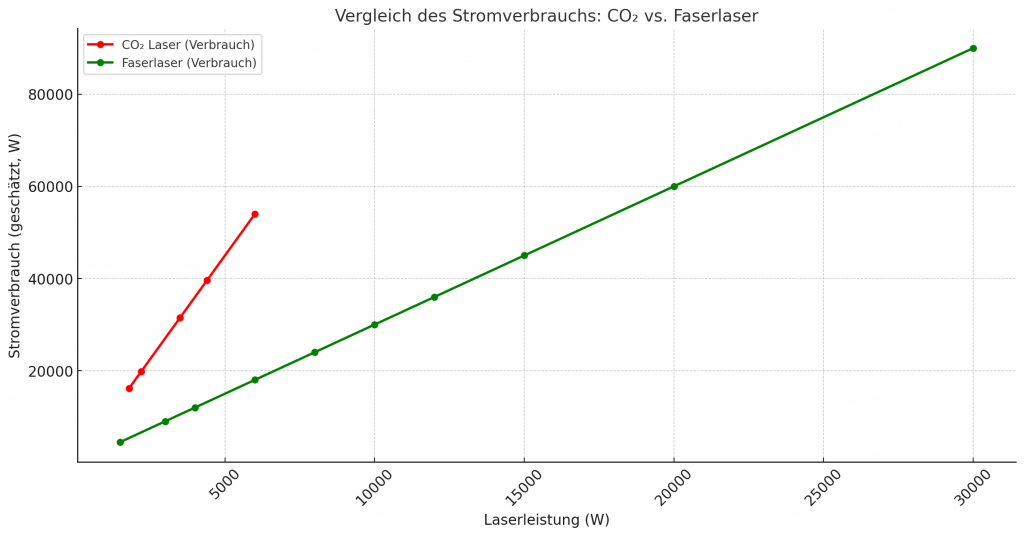

Depending on utilization, savings of several tens of thousands of euros per year are possible.

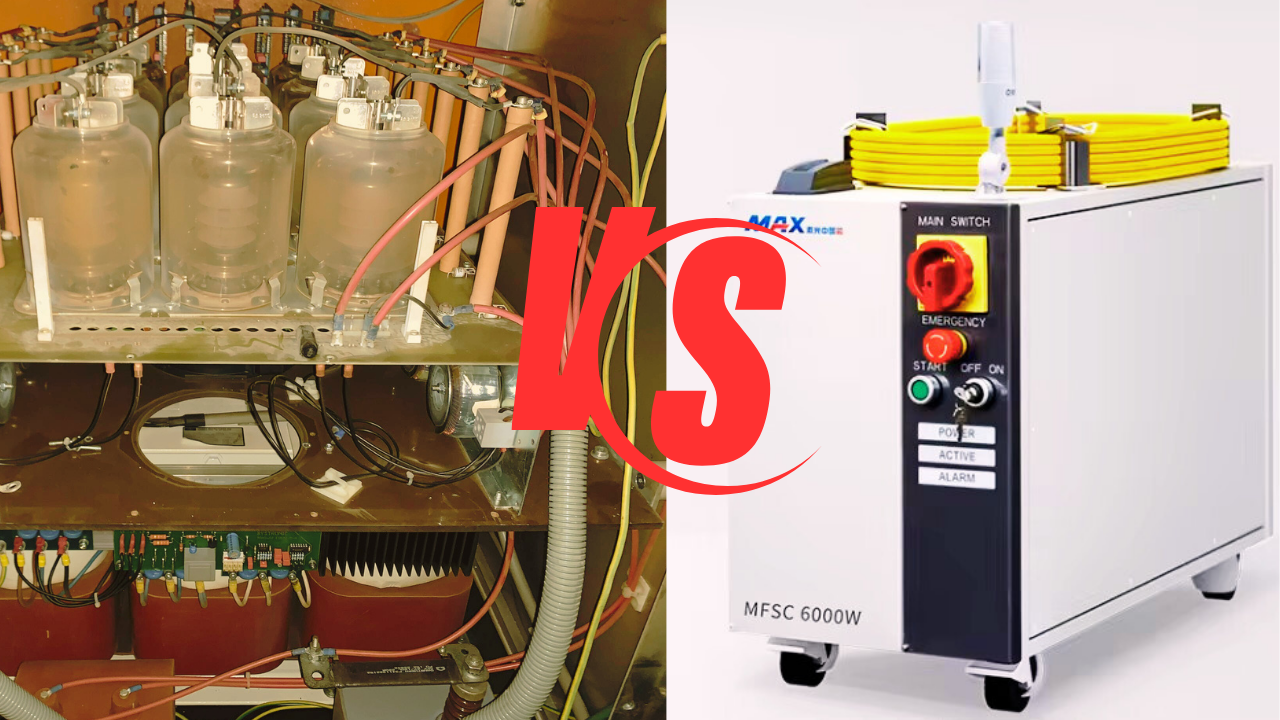

Yes – as long as the mechanical structure and axis systems are intact, a retrofit is no problem.

Trust in professional systems that keep you ahead – for maximum efficiency, safety, and operator convenience.

Trust in professional systems that keep you ahead – for maximum efficiency, safety, and operator convenience.