Upgrading to fiber laser technology reduces maintenance requirements, lowers energy costs, and enables more precise cutting of thin materials. At the same time, it extends the lifespan of your existing machine

Expert Bystronic repair, performance-boosting upgrades, and premium used Bystronic lasers – everything you need in one place

Bystronic repair, machine upgrades, and the purchase of used Bystronic lasers – we provide tailored technical solutions for every requirement.

Our services are designed for industrial companies that demand precision, efficiency, and long-term operational reliability.

Whether it’s the professional repair of a CO₂ laser machine, retrofitting to modern fiber laser technology, or purchasing certified pre-owned systems – our experienced service team is at your disposal throughout Germany.

We work fast, reliably, and with the goal of minimizing your production downtime. Count on certified technology, transparent advice, and years of expertise with Bystronic machines

Bystronic service – Fast, reliable solutions for maintenance, repair, and upgrades of Bystronic laser machines.

Learn more on our German page

For detailed information about Bystronic service, CO₂ → fiber laser retrofits, upgrades, and certified used machines, visit:

Bystronic Service – Reparatur & Upgrade (Deutsch)Internal link (EN → DE) with keywords: Bystronic service, CO₂ to fiber laser retrofit, Bystronic upgrade.

Expert Bystronic Laser Service & Repair – Maximize Uptime and Ensure Reliable Production

Bystronic laser service and repair are essential for the long-term performance and reliability of your laser cutting system.

Our certified technicians carry out both preventive maintenance and fast, professional repairs directly at your site – ensuring your production never comes to a halt.

We provide a comprehensive service for your Bystronic machines: from regular maintenance (Bystronic maintenance) and technical servicing to the rapid resolution of faults, control system issues, or mechanical breakdowns.

With precise fault diagnostics, short response times, and the use of genuine spare parts, we ensure the sustainable performance of your machine.

Rely on a partner with deep expertise in Bystronic repair and a service commitment you can truly trust.

CO2 to Fiber Laser Upgrade – Maximize Efficiency and Secure the Future of Your Bystronic System

Retrofit CO2 to fiber laser solutions from our expert team help you modernize your Bystronic machine, improve cutting quality, and reduce operating costs – all at a fraction of the price of buying new

The technological shift in sheet metal processing makes the move from CO₂ to fiber laser systems inevitable.

With our Bystronic upgrade, we transform your existing CO₂ machine into a powerful, modern fiber laser system – without the need for a complete new purchase.

What this means for you:

Lower maintenance costs

Higher energy efficiency

Reduced cutting costs

Significantly better cutting quality for thin to medium materials

Our experienced team of technicians takes care of the entire retrofit, including:

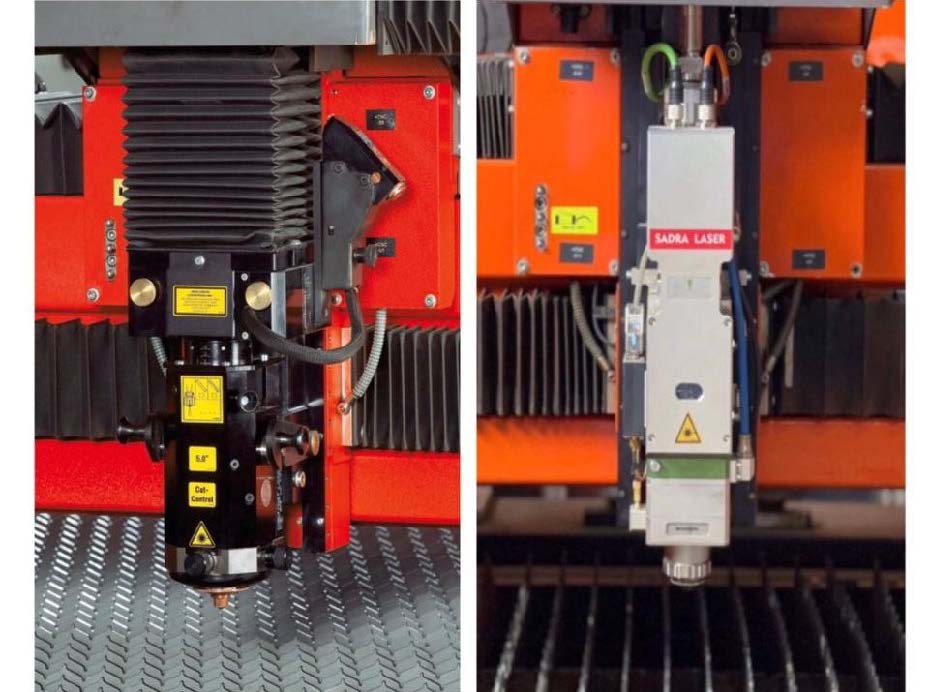

Removal of the CO₂ source

Integration of a new fiber laser source

Adjustment of control, cooling, and safety systems

Final system test and production start

CO₂ to Fiber Laser has never been easier – invest in performance, not downtime.

Buy or Sell Used Bystronic Lasers – Inspected Machines, Proven Quality, and Complete Service Support

The market for used laser cutting machines offers great opportunities – if you have the right partner by your side.

With us, you can buy a used Bystronic laser or sell your machine at a fair price – quickly, transparently, and professionally.

Our available machines – including used Bystronic fiber lasers – are carefully inspected, cleaned, and offered in excellent technical condition. For buyers, we provide comprehensive consultation, commissioning support, and optional after-sales service. For sellers, we handle valuation, marketing, and the complete transaction process.

Whether you’re looking for a reliable entry into fiber laser technology or want to resell your existing system – we have the right solution for you.

Looking for a Bystronic laser for sale? We offer a wide range of inspected pre-owned Bystronic laser cutting machines, including both CO₂ and fiber laser models – all tested, certified, and ready for production

⚡ Upgrade Your Bystronic Laser – More Power, Less Cost, Maximum Efficiency

Bystronic Power Upgrades give your machine a second life – without the cost of a new one.

Our upgrade solutions are perfect for companies looking to boost performance, increase productivity, and extend the lifespan of their current Bystronic laser systems.

Whether it’s replacing a CO₂ laser source with a modern fiber source, upgrading cutting heads, or improving software and cooling systems – we help you stay competitive with the latest technology at a fraction of the cost.

🔧 Typical Upgrades Include

CO₂ to Fiber source conversion

Cutting head & sensor modernization

New-generation software & control systems

Power supply & chiller optimization

🎯 Why Choose a Power Upgrade Instead of Buying New?

Save up to 60% vs. new machine costs

Reduce energy consumption & maintenance needs

Enhance cutting quality and reliability

Faster turnaround & minimal downtime

Full consultation, installation & service support

Whether your goal is to improve productivity or delay large capital investment, a Bystronic Power Upgrade is a smart, future-proof decision.

Our many years of experience with Bystronic laser cutting systems enable us not only to carry out precise repairs, but also to implement technical upgrades – from replacing individual components to complete retrofits from CO₂ to fiber laser technology. For more detailed information about original Bystronic technology and machine architecture, you can also visit the official website of the manufacturer.

✅ Bystronic Laser – Upgrade from CO₂ to Fiber or Buy New?

Laser technology is evolving rapidly. Companies operating with older CO₂ systems often face a key decision: should you retrofit or invest directly in a new Bystronic laser?

In this article, you’ll discover the available options, the advantages and disadvantages of a Bystronic upgrade, and when switching to fiber laser technology truly pays off.

🔧 Why a Bystronic Upgrade Can Be a Smart Choice

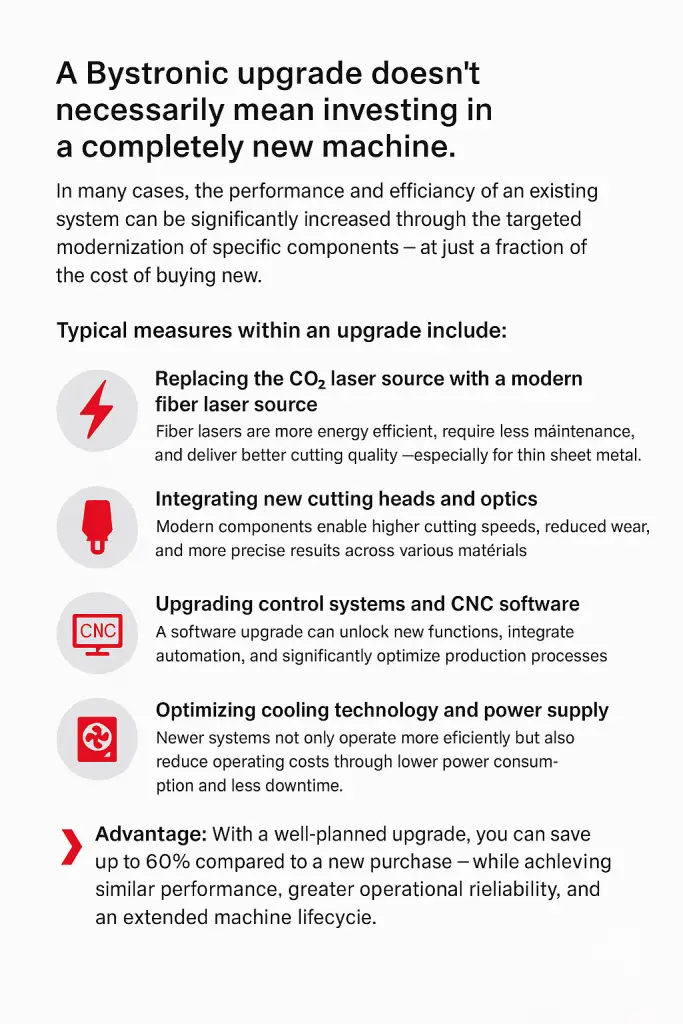

A Bystronic upgrade doesn’t necessarily mean investing in a completely new machine.

In many cases, the performance and efficiency of an existing system can be significantly increased through the targeted modernization of specific components – at just a fraction of the cost of buying new.

Typical measures within an upgrade include:

Replacing the CO₂ laser source with a modern fiber laser source: Fiber lasers are more energy-efficient, require less maintenance, and deliver better cutting quality – especially for thin sheet metal.

Integrating new cutting heads and optics: Modern components enable higher cutting speeds, reduced wear, and more precise results across various materials.

Upgrading control systems and CNC software: A software upgrade can unlock new functions, integrate automation, and significantly optimize production processes.

Optimizing cooling technology and power supply: Newer systems not only operate more efficiently but also reduce operating costs through lower power consumption and less downtime.

➡ Advantage: With a well-planned upgrade, you can save up to 60% compared to a new purchase – while achieving similar performance, greater operational reliability, and an extended machine lifecycle.

A targeted CO₂ to fiber laser retrofit is therefore not only environmentally sensible but also highly cost-effective – especially for companies that want to stay flexible without compromising on modern laser technology.

💡 CO₂ to Fiber Laser – Technology Shift for the Future

💡 Why Switching from CO₂ to Fiber Technology Is a Future-Proof Investment

Upgrading from CO₂ to fiber laser technology represents a decisive technological leap for many companies. While CO₂ laser machines have delivered reliable performance for years, it is now increasingly clear that fiber lasers outperform them in almost every aspect – both technically and economically.

Key advantages include:

Higher energy efficiency: Fiber lasers convert electricity into laser power far more effectively, resulting in significantly lower energy costs, especially in continuous operation.

Reduced maintenance requirements: Fiber lasers require no mirrors, no resonator-related adjustments, and no complex gas cooling – saving both time and materials.

Better cutting quality for thin to medium materials: Thanks to the smaller beam focus diameter, fiber lasers provide more precise cuts, cleaner edges, and less post-processing, especially for sheet thicknesses under 10 mm.

Simpler design without optical mirrors or gas flow: This reduces the potential for faults and increases the overall system’s reliability.

Many users report up to 50% lower operating costs after switching to fiber – a factor that is becoming increasingly important with rising electricity prices and a growing focus on sustainability.

Investing in a CO₂ to fiber laser upgrade often pays for itself within just a few months through reduced operating costs, minimized downtime, and increased production capacity.

🛠️ When Is It Worth Buying a New Bystronic Laser?

🛠️ Buying New Instead of Upgrading? When a New Bystronic Laser Machine Makes Sense

In many cases, a Bystronic upgrade is economically sound – but not always. The deciding factor is the condition of your existing machine. A retrofit or partial upgrade can only be implemented efficiently if the base structure is stable and the current technology can be modernized.

However, if:

the control system is outdated,

the chassis shows significant wear,

or safety-critical components no longer meet current standards,

…then purchasing a new or used Bystronic laser cutting machine can be the more cost-effective long-term solution.

For companies focused on maximum production speed, automation, and digital integration, buying a new machine is the next logical step. Options include, for example:

BySmart Fiber – a reliable solution for medium production volumes

ByStar Fiber – for maximum performance and complex cutting tasks

Pre-owned models from previous series – cost-effective and often available with warranty

➡ Tip: If you plan to buy a Bystronic laser, don’t underestimate used machines. Many of these models have been refurbished, tested, and are offered with a maintenance package, training, and optional on-site installation – a smart alternative to a brand-new unit.

📌 Conclusion: How to Choose Between a Bystronic Upgrade and Buying New

A Bystronic upgrade is an ideal solution for companies that want to save costs while staying technologically up to date.

For those seeking maximum flexibility, automation, and future-proofing, purchasing a new or used Bystronic laser offers a long-term solution.

Get tailored advice – we analyze your machine and help you choose the best strategy for your needs.

✅ Conclusion – Modernize Your Bystronic Laser or Invest in a New One?

Whether you choose a targeted Bystronic upgrade or decide to buy a new Bystronic laser, the right choice depends on your current machine condition, production volume, and long-term plans.

Upgrading from CO₂ to fiber laser offers a cost-effective way to modernize existing machines while reducing operating costs.

A well-planned technology shift not only boosts your competitiveness but also increases your production efficiency.

Rely on our expertise to make the right decision – tailored to your needs, independent of the manufacturer, and economically sound.

FAQ – Bystronic Laser Service, Repair & Upgrade

Can I retrofit my old Bystronic CO₂ laser machine?

Yes, we offer a complete retrofit package for many common Bystronic models. This includes replacing the CO₂ laser source with a modern fiber source – along with control system upgrades, cooling enhancements, and safety adjustments

Is a Bystronic upgrade cheaper than buying a new machine?

Absolutely. A professional upgrade often costs only a fraction of a new system – while delivering nearly identical performance and features

How do I know if an upgrade is worthwhile for my machine?

Our technical team inspects the condition of your system and provides a tailored recommendation, taking both technical and economic factors into account.

Is financing available for upgrades or used machines?

Yes, we work with financing partners and offer leasing as well as installment payment options – for both upgrades and used systems

Are used Bystronic lasers available for purchase?

Yes, we regularly offer inspected, pre-owned Bystronic laser cutting machines – including both CO₂ and fiber laser models

How can I sell my used Bystronic machine?

Send us the machine details (model, year of manufacture, condition). We will provide a free valuation and assist with marketing, collection, and the entire transaction process

What is included in the Bystronic upgrade package?

Our package includes the delivery and installation of the new fiber laser source, control system modification, safety system adjustments, as well as functional testing and operator training.

How long does a CO₂ to fiber retrofit take?

In most cases, the complete retrofit takes 7 to 14 working days – depending on the machine type and specific requirements

Do you provide training after the upgrade?

Yes, after each retrofit or installation, your staff will receive comprehensive training on the operation, maintenance, and safety of the new technology

Modernize Your Bystronic Laser or Buy Pre-Owned – We Offer Personalized Advice!

Benefit from our expertise in CO₂ to fiber laser upgrades and in purchasing certified Bystronic laser cutting machines.

Together, we’ll find the right solution for your production – fast, efficient, and cost-effective.